Phosphate chemicals protect metals from corrosion and increase its resistance to wear for further application.

The phosphate coating is an ideal base for subsequent painting, liquid paints, powder coating, oil coating, rubber coating and cold forming.

There are three major reasons for phosphating benefiting your process.

Vanphos is an iron phosphating chemical for painting surfaces. Iron phosphate surface exhibits mechanical property so iron phosphate surface can be welded. It contains no toxic and harmful chemicals, so waste disposal is very simple.

For heavy rust and oil, separate degreasing and de-rusting chemicals should be used.

Everphos is a calcium modified chemical for painting surfaces. Everphos produce fine smooth zinc phosphate coating on the properly cleaned metal surface. Its fine crystal formation ensures minimum paint shrinkage into the phosphate layer and hence minimum gloss reduction.

Triphos is tricationic phosphating chemical for painting surface. Typical uses include car accessories, metal cases, signs, stampings, washing machine cabinets, and sheet metal parts. It is particularly recommended for articles, which will have to withstand severe climate conditions after painting.

Galphos is a phosphating chemical for painting in the galvanized surfaces. Galphos produces fine smooth zinc phosphating on the properly cleaned galvanized metal surfaces.

Aluphos is a phosphating chemical for painting on aluminium surfaces. It is chrome free chemicals for corrosion prevention and protection for aluminium surfaces. Phosphated surface in Aluphos is ideally suited for organic finishing (painting or powder coating) surface. Phosphated parts in Aluphos can be welded prior to the organic coating that gives out standard mechanical properties.

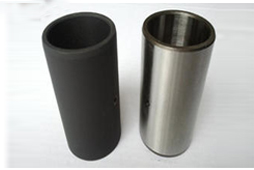

Surphos is a phosphating chemical for oiling surfaces. It produces phosphate coating on cleaned steel and zinc surface. The components are phosphate coated and sealed with suitable rust preventive oil. Surphos is ideally suited for use on moving parts such as piston rings, gears and crankshaft. It forms a coating integral with the metal and when oiled it will be used as a bearing surface which holds the oil between the moving parts.

Drawphos is a phosphating chemical for cold forming components. It forms heavy Zinc phosphate on a properly cleaned ferrous surface.